Wholemeal flour can be used for the production of alcohol destined for human consumption.

The distilling industry normally uses cereals with very low specific weight, between 0.65 and 0.72 kg/l. These are foods that have been damaged, probably during cultivation, by the elements leading to compromised or halted development, making it unsuitable for food production.

The damaged food that will in any case by treated in order to try to save the starch content, is therefore spread with antifungals, pesticides and gas and chemical preservatives to maintain the characteristics until its transformation.

Pre-treatment and cleaning

Before distillation it is necessary to proceed with a treatment to clean the surface of the grain to prevent contaminants such as weed killers, insecticides and pesticides and antifungals from being absorbed by the alcohol, altering the flavour and lowering the quality. It is thought that removing 0.5% of the husk is sufficient to obtain a good product, ready for the successive milling process.

This process is above all necessary with clear spirits such as vodka and gin, which are not subjected to further processing or flavouring in the barrel.

Milling

This stage can involve different processes, even if, for a good finished product and therefore, a good spirit, requires the right calibration process for the molecular structure. Very often, the grain is prepared using hammer mills that impact on the kernel in a destructive, irregular manner, causing it to form an irregular structure in terms of form and also size, with uneven results. This appearance should not be neglected since it is the shape, thickness and size that affect the distillation process. A process, however, which is correct and effective, is roller milling, which can guarantee greater constancy in terms of shape, size and thickness. Of course, the process develops vertically, using further processing machinery, such as plansifters, centrifugal impact detachers, filters and other accessories. This plant technology makes it possible to achieve extraordinary results, also from a productivity viewpoint, arriving at using over 95% of grain with grain sizes of under 1000 micron.

Fermentation and distillation stages

The last stage is of course the grain transformation stage, or in other words, fermentation to extract starch and transform it enzymatically into alcohol. This process takes place in complex plants, all strictly built in stainless steel, using different transformation steps: boilers, decanting tanks, pressurised systems, as well as coolers and distillers in a continuous process that lasts several days.

Vodka is one of the most widely produced spirits. It has no particular character, aroma, taste or distinctive colour. These properties are developed during the distillation process, which may be repeated more than once. At the end of the process, the alcohol can be filtered through active carbon or other substances. Normally, vodka is not aged and can be made using grain, potatoes, sugar, fruit and any other raw material that can be fermented to produce alcohol. This means that vodka is the quickest and cheapest spirit that can be made, thanks to the easy availability of its ingredients.

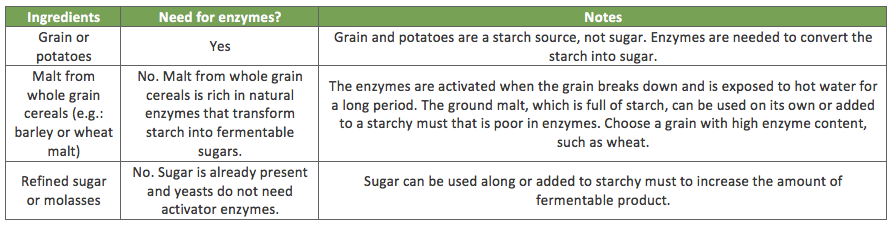

Whatever the basic ingredients were, it is important to remember that it needs to contain sugars or starch to trigger the production of alcohol. Yeast, in fact, eats the sugar or starch to release alcohol and carbon dioxide.

When making vodka from corn or potatoes, it is necessary to prepare a must that contains active enzymes able to break down the starch into fermentable sugars.

To conclude, what can we obtain from grain that is not suitable for human consumption? A lot. The aim is always not to waste anything that nature has to offer, so that even the food from damaged grain can still be used to make alcohol for sale and consumption.

luigi@omasindustries.com

CEO