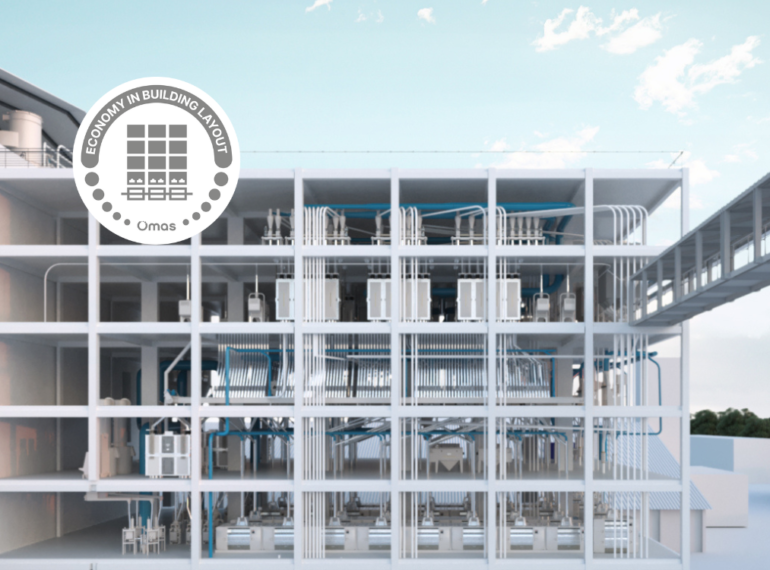

The introduction in the milling market of the Leonardo roller mill – Omas torque pick-up version, has introduced considerable advantages, in fact revolutionizing the classic idea of industrial mill with floors. The innovations involved both plant designers, responsible for the design, and end users, who are usually entrusted with the supply of buildings.

At plant level, Leonardo Roller Mill guarantees total freedom and versatility of placement. It can be considered a plug-and-play machine. The elimination of the transmission (motors, pulleys and belts), whether on the same floor or on the floor below, allows to install the machine in any floor easily integrating it both in new and existing plants.

The advantages related to direct motorization (energy efficiency, safety of use, material saving and maintenance) in the pick-up version also translate into the real possibility of:

- completely eliminating a floor (the one usually used for motorization)

- install several machines with equal space in case of motorization on the same support plane (the standard distance between two roller mills with 8 rollers of length 1250 mm, is only 2650 mm).

The above, is immediately reflected in the design of the buildings that are geometrically more compact and short. The structure will load less weight on the foundation and the structure will be lighter. Precisely in this regard, it is important to bear in mind that roller mills are the heaviest machines among those of the process, moving them to a higher level involves an increase in the center of gravity with relative stresses to be considered and counterbalanced.

To support this, we compare for example a multi-storey system (steel structure and hi-bond floors) with soft wheat with daily production of 500 t in the Omas building economy layout (3 floors) compared to a classic one (5 floors):

- volume saving: 12%;

- or saving loads on the foundations: 6-8%;

- or Material savings: 15% carpentry (about 30 t), 18% corrugated metal sheets (about 240 m2), 10% sandwich panels (about 350 m2);

- or total investment savings (civil works and structure): 12%.

This is what we in Omas call reinventing, one of the many key assets that only Leonardo can offer.