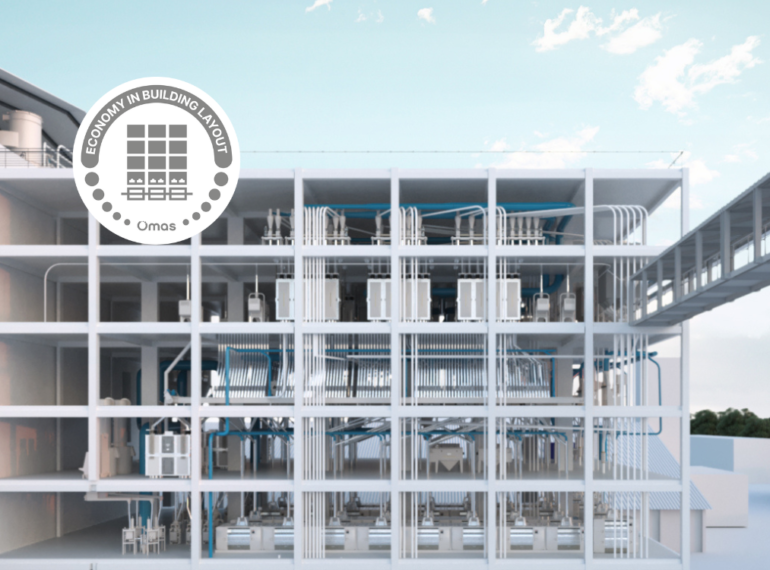

Omas economy in building layout

The introduction in the milling market of the Leonardo roller mill – Omas torque pick-up version, has introduced considerable advantages, in fact revolutionizing the classic idea of industrial mill with floors. The innovations involved both plant designers, responsible for the design, and end users, who are usually entrusted with the supply of buildings.

At plant level, Leonardo Roller Mill guarantees total freedom and versatility of placement. It can be considered a plug-and-play machine. The elimination of the transmission (motors, pulleys and belts), whether on the same floor or on the floor below, allows to install the machine in any floor easily integrating it both in new and existing plants. Continue reading Omas economy in building layout