How is wheat ground? How is flour made? What is the difference between durum wheat and soft wheat? There are lots of questions to be asked when choosing the right products to buy, when it comes to making careful, aware choices about diet.

The starting point, when answering these questions, is to look at the origin of milling wheat: how is it ground and how is the structure of the wheat grain organised?

Grain the properties and characteristics of the dry dehiscent fruit

The generic term “grain” is universally associated with the Triticum aestivum plant, a favourite variety for the production of white flour and which takes its name from the season in which it turns ripe, summer.

Like all plant species from the Poaceae family, it produces dry dehiscent fruits in regular rows that create the ear shape.

The fact it is classified as a dry fruit comes from the lack of water content (less than 20%), while the term “dehiscent” means that the fruit does not expose its seeds to the outside during their ripening process; it is necessary to specify that although compact, the grain actually has a highly complex structure, where the germ parts, the actual “seeds” are a mere fraction, just 3%.

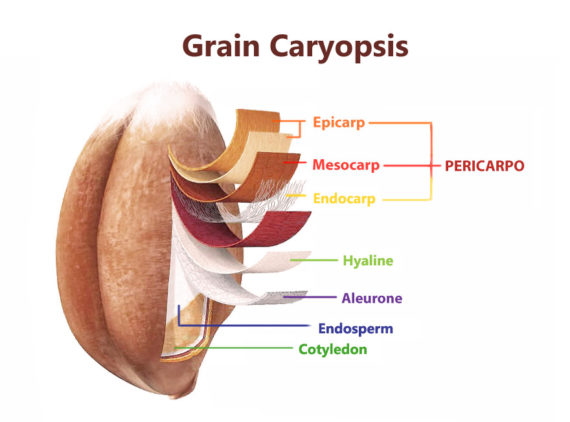

All major cereal plant families have fruits of this type, which are also known as kernels. The wheat kernel has a layered structure in which each part contains the next one, like a Russian doll, until we reach the innermost part, the germ, which is surrounded by layers of food reserves.

Outer casing

The first structure that can be observed on the fruit is the outer casing, which is formed by a series of 3 fibrous membranes, rich in cellulose fibre, the molecule that is essential for adding rigidity to the plant stem. These coatings are known as, from the outside in, epicarp, mesocarp, and endocarp. Together, they form the pericarp, the protective organ that once ground, will form the bran, which has beneficial properties for colon and intestine and has been widely revalued after many years of being considered a waste product.

The endosperm, source of nourishment for plant development

Below the casing formed by the bran is the more consistent part of the fruit. It takes up around 80% of the overall volume and it is known as the endosperm. It is a store of starch that is used by the germ of the plant to feed itself as it develops and until it is large enough to feed independently using photosynthesis. It is also the portion that is ground to make flour during the milling process.

The endosperm has two membranes, the innermost layer, known as the aleurone, which is rich in fat and protein, and an outer layer, or hyaline layer, consisting of a film of transparent, elastic cells.

The shoot, the life of the plant

At the base of the germ is the shoot that will give life to the plant. It consists of 3 parts:

- An embryonic leaf, or cotyledon, which conveys the stored starch to nourish the shoot, just like an umbilical cord;

- Two meristems, tissues with cells that are as yet undifferentiated and which allow growth: one is located at the top end (apical) and will cause the stem to grow, while the other is located at the bottom end (radical) and will develop the roots;

- A hypocotyl, a structure between the two meristems, acts as a support and provides the growth axis of the plant.

The molecular composition of grain

Once the ’“anatomy” of the grain has been reconstructed, it is possible to take a deeper look at a submicroscopic level, and to analyse its composition on a molecular level:

- Water: this is from 8 to 18% of the fruit, depending on level of ripeness;

- Sugars: the dominant part and 72% of the fruit;

- Fats: around 1.5-2%;

- Minerals: such as lipids, these take up 1.5 – 2% of the grain;

- Proteins: on average, around 12% A large part is contained in the endosperm; starch storage, and some (gliadin and glutinin) form gluten in contact with water.

Grain and milling the benefits of roller milling

It is necessary to process the grain to make its nutrients necessary, starting with milling and grinding.

Stone grinding, the oldest form, preserves all of the nutritional properties of the grain intact. In modern roller milling, on the other hand, increased temperature caused through the hearing of the machine may involve a partial loss of heat-sensitive vitamins and enzymes.

This technique does have many merits, but the most important is the possibility to separate the 3 main parts of the grain (casing, grain and starch reserve), which is not possible with the traditional method.

Thanks to this advantage, it is possible to obtain different types of flour according to the parts of the grain used in the milling process: wholegrain flour (with the highest protein content) which is made by grinding the whole grain without removing the bran from the outer membranes; through to 00 flour, made using just the endosperm, consisting of pure starch, and widely used to make cakes.

The useful part of the grain varies from 100% for wholegrain flour to the 70% required for 00 flour.

As we have seen, a grain of wheat has a very complex structure, featuring different casings and membranes containing the germ, the source of plant life, and packed with potential from a food point of view, with countless beneficial nutritional properties.

To make the milling process optimum, it is therefore essential to be extremely familiar with the characteristics and properties of the grain in order to obtain different, qualitatively excellent types of flour.