During the durum wheat milling, the grinding diagram is well studied in order to obtain the highest percentage of semolina and flour from the incoming wheat.

The semolina, the main product of durum wheat, is collected and separated by machines called seeders. They work using 2 fundamentals, calibration and specific gravity, which are responsible for separating and selecting the semolina grains (although still dirty) coming from the Plansifter.

Plansichter and rolling mill, for the selection and grinding of the product

The Plansichter then collects all the grinding product and, due to the different seals inside it, selects the product depending on its grain size and send it to the next step.

Each product selected by the Plansichter comes from its own mill passage.

The rolling mill is the main machine of the mill, it has the task of milling the wheat on the first mill passage and all the other grinding products previously sifted and selected by the various machines.

How to get the best quality from semolina? The 4 factors that influence the milling process

The Milling stage is the most important in our mill, and it is possible to obtain a larger and higher percentage of semolina thanks to the 4 following main factors:

- Rifling angle

The iron shape used by the grinding rollers to work the grain at B1 and the various products on the subsequent grinding steps are the main reason for a high extraction of semolina and its quality.

Considering the same lines per centimeter, lines with a more acute and / or narrow angle are able to produce larger semolina grains than the more obtuse and / or open corners.

For this reason, the rifling table with the parameters is an extremely important element.

The rifling angle is a fixed parameter that cannot be changed by the operator during milling.

- Rollers peripheral speed

Grinding rollers peripheral speed during their work is recommended based on the work load and the product to be obtained.

At the moment of contact between the lines, excessive speed leads to chalking of the processed product. In durum wheat we know that the peripheral speed expressed in m / sec varies from 4.5 to 5.5 m / sec.

We at Omas are the only ones able to control and modify this parameter at any time thanks to the DD technology (Torque Motors – controlled by inverters). In fact, Omas is able to better customize the peripheral speed of each step and to insert this in the various grinding recipes. The other rolling mills are characterized by fixed turns, different from Leonardo, the Omas rolling mill.

- Working distance (GAP) of the milling and/or pressure rollers

The result is directly proportional to the pressure exerted by the rollers: the more the passage is closed, the higher the production of thin semolina produced by the rollers will be.

This parameter, the GAP / Distance represents the only parameter that companies can provide to the mill operator in order to modify and / or improve the yields and performance of the grinding, as all the other parameters are fixed. This parameter can be inserted in the working recipes.

- Ratio 1:2,5 for grooved rollers (Standard)

It is the speed ratio between fast and slow grinding roller.

Thanks to the Leonardo rolling mill, Omas is able to change the ratio at any moment of the milling, guaranteeing maximum performance in all working conditions.

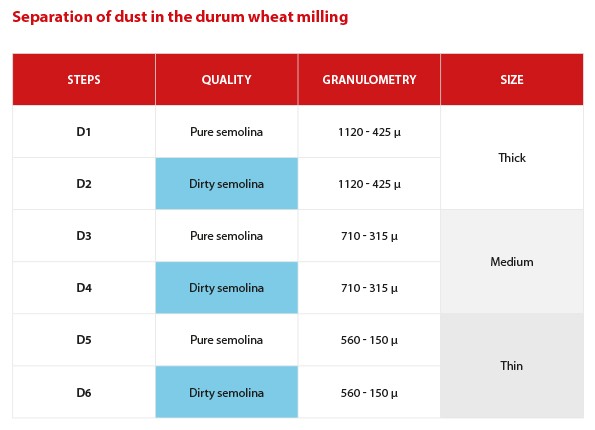

We know that in a grinding diagram there are many products to be processed, both in terms of size and quality.

A durum wheat diagram is made up of:

- Coarse breaking steps 2 – 3 – 4 – 5BC

- Fine breakage steps 3 – 4 – 5 – 6F

- Semolina steps dressed D1C – D2C – D3C – D4 – D5

- Clean semolina passages D1F – D2F – D3F

- Refining steps RS1 – 2

Every step produces very different products, so it is almost impossible to establish that the same type of Ratio can give the best grinding performance.

The Leonardo rolling mill, equipped with the Flexy Mill system, is able to adapt to the best, meeting the different needs of the product to be processed.

It then might have different configurations and it changes in real time the data element concerned, according to the type of grain, its size, its viscosity and its hardness.

Small speed changes between grooved rollers lead to consistent increases in semolina production.

In addition, it could be verified that reducing the grinding ratio by a few decimal places, excellent results are obtained in several respects:

- Significant chalking reduction, gaining a higher percentage of semolina;

- Reduction of the damage to starches, an important value required by all pasta lines;

- Roundness reduction of the produced semolina grains;

- Significant sharp edges reduction on the semolina grain. The semolina roundness significantly influences the quality of the semolina, with an increase in color and a greater yield during the drawing of the pasta.

Sergio Dipasquale

sergio@omasindustries.com

Chief Milling Technologist